KEROSENE FIRE LAMP

Driven by the desire for a gently flickering flame during winter, I embarked on crafting a kerosene landscape lamp. What began as a simple idea revealed unexpected detail in many aspects, from wick stability to heat control, demanded meticulous attention. This project log captures those lessons. Because winter, after all, calls for the warmth of fire.

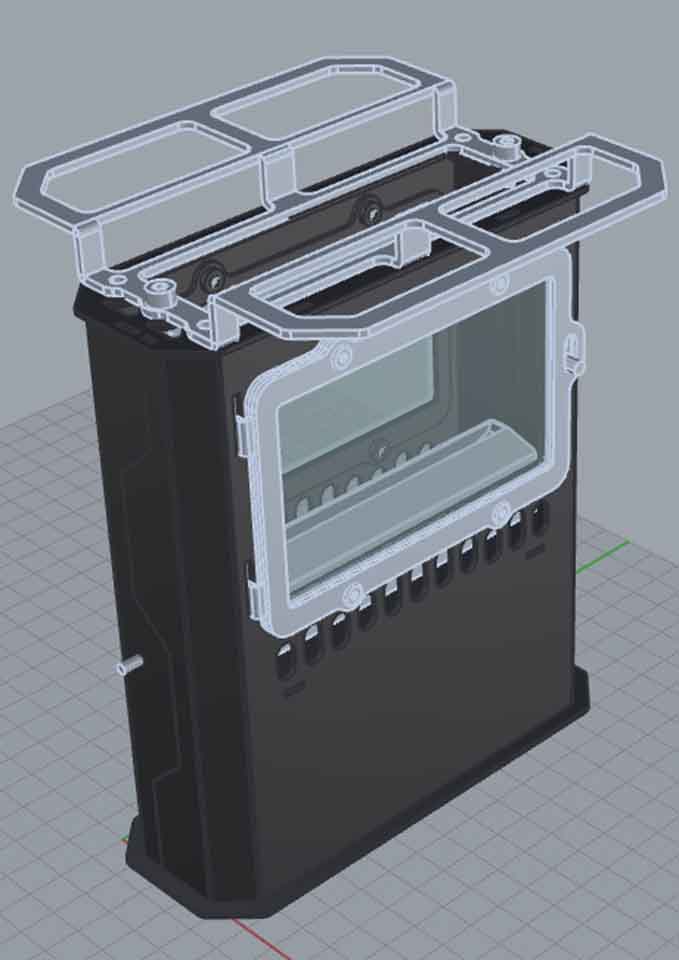

V1 | THE FIRST ATTEMPT

- Date: 2024 NOV

- SoftWare: Rhino

- HardWare: Sheet metal; Quartz glass

- Description: I assembled every possible material I could think of, stacking them high with nothing but blind optimism for a first-try victory.

The First Attempt

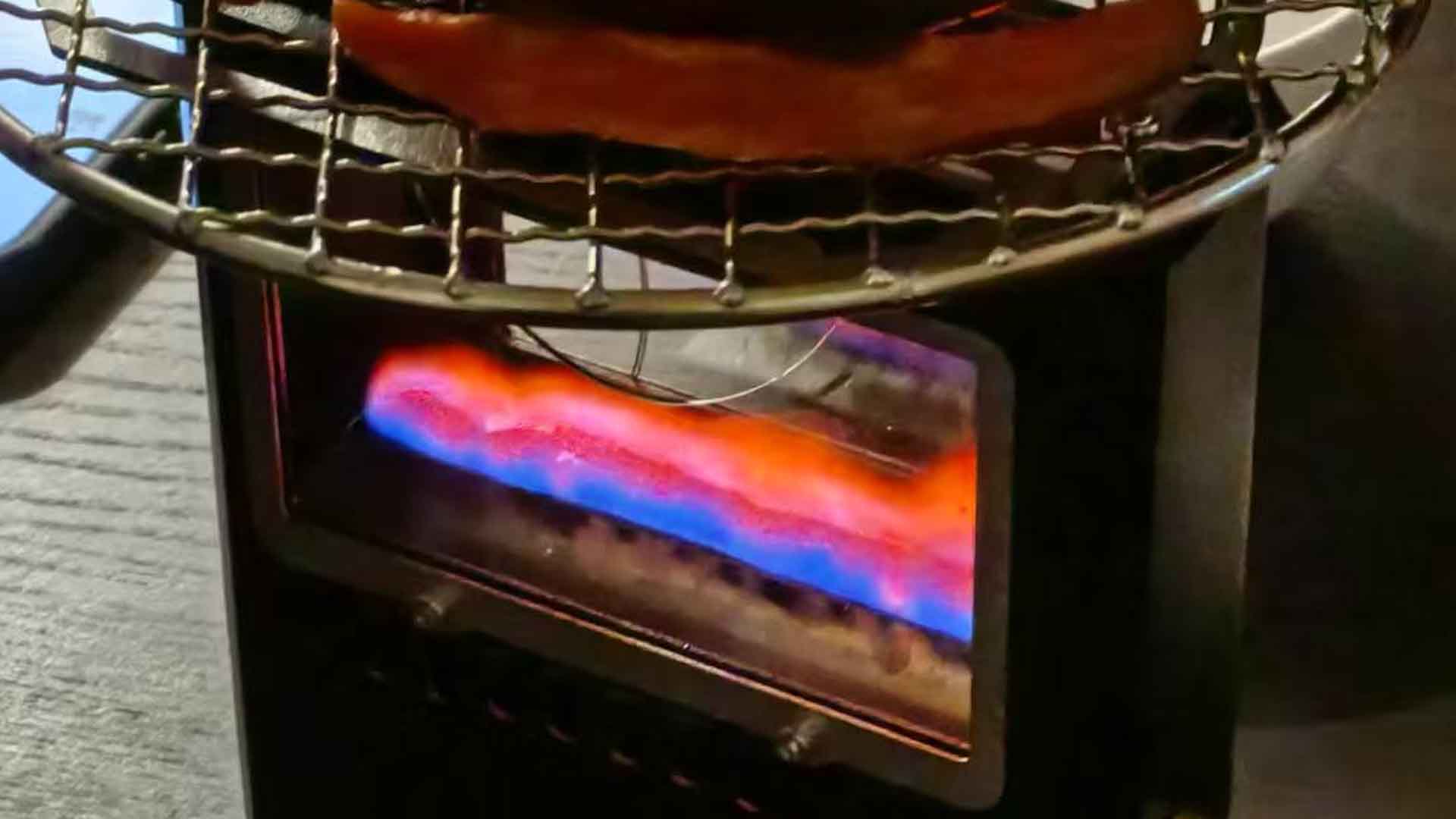

The first lighing attempt succeeded effortlessly - with just kerosene and a wick, the flame ignited perfectly. To my surprise, the flame intensity proved idea for roasting fruits, effectively warming my stomach on cold winter nights.

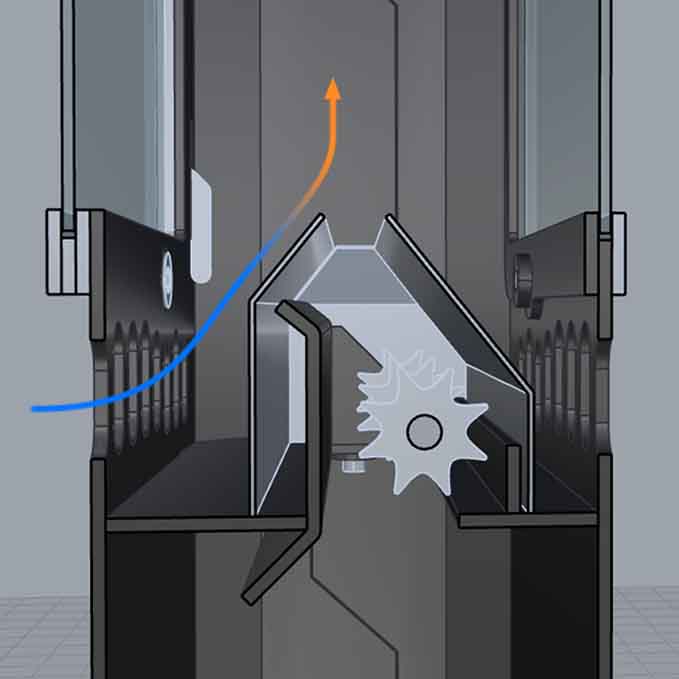

Air Flow: The ventilation holes direct airflow straight at the wick, causing significant flame flickering in windy conditions and making it prone to extinguishing.

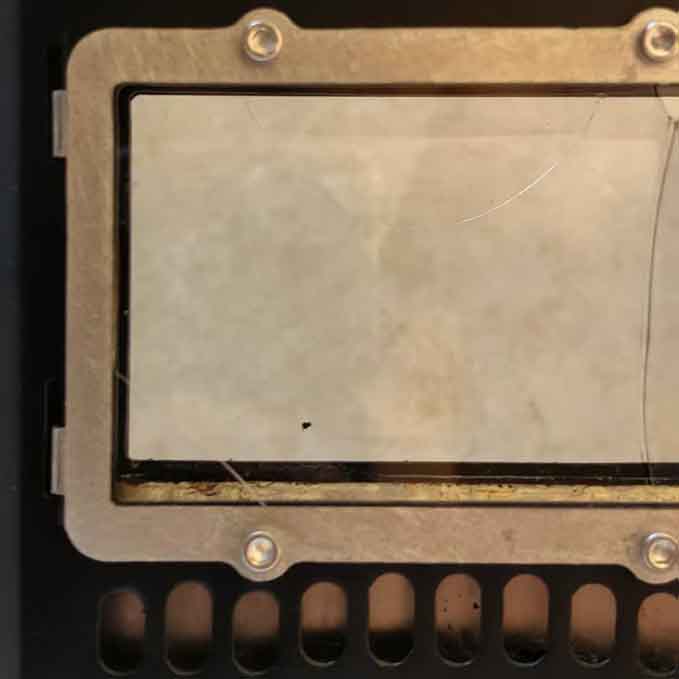

Gap Control: Despite allocating a 0.1mm clearance for the glass panel, sheet metal deformation and welding marks during fabrication ultimately caused the quartz glass to crack under pressure.

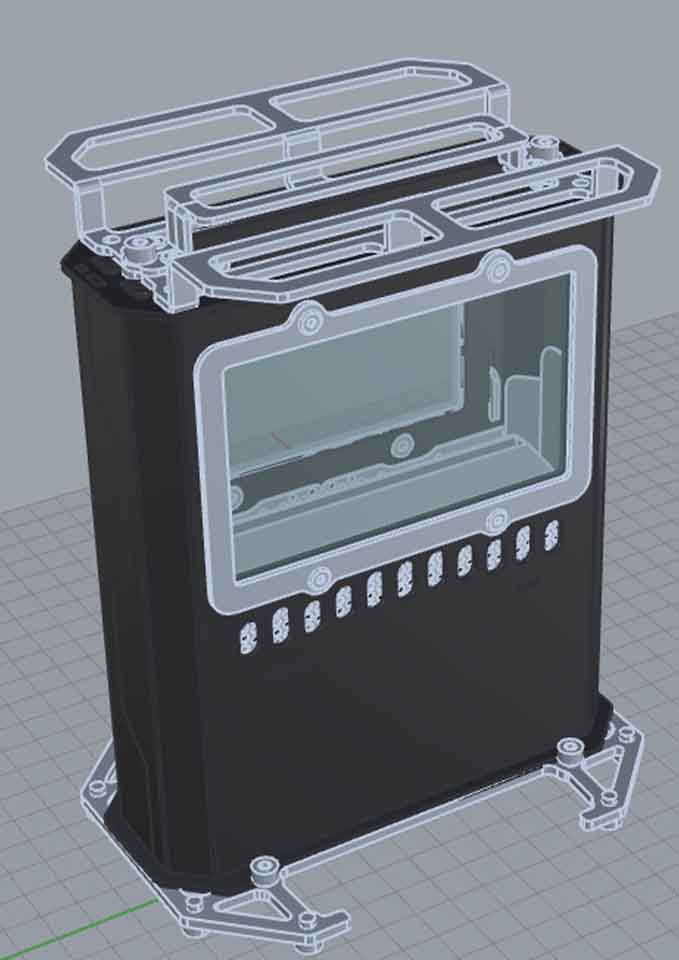

V2 | UPDATED LAMP

- Date: 2025 JAN

- SoftWare: Rhino

- HardWare: Sheet metal; Quartz glass; Stainless steel

- Description: The redesigned lamp incorporates enhanced structural details, achieving significant improvements in both operational stability, and weight.

The Updated Lamp

This generation keeps the original's warm glow but stands steadier, holds stronger, and laughs at the wind - now I can only blow it out from the top or lower the wick, patiently wait for the flame to sleep.

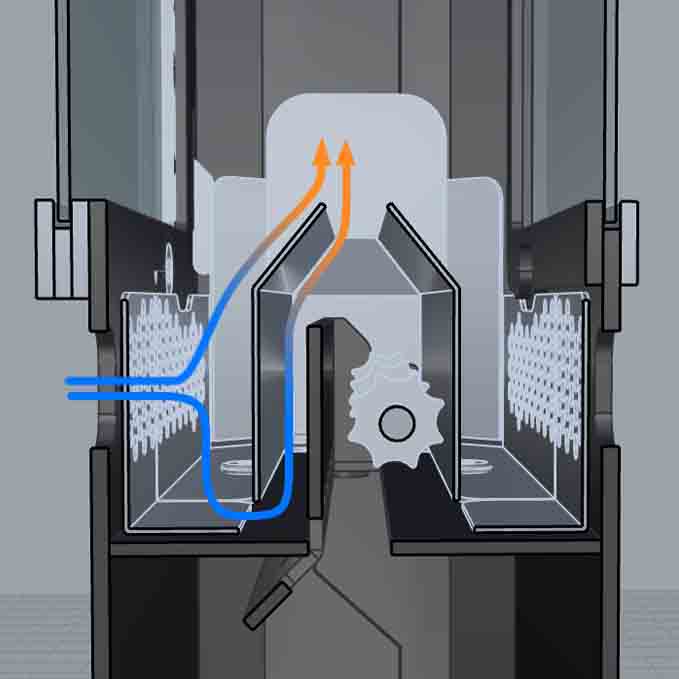

Thermal & Windproof Design: This model integrates a stainless steel heat shield and wind screen to block radiant heat and gusts. An internal air duct within the burner cap stabilizes combustion airflow. However, this over-engineered airflow system inadvertently eliminated natural flame extinction mechanisms, and requires top-down airflow for shutdown.

Optimized Burner Cap: Redesigned burner cap now hugs the wick tightly, reducing the problematic air ducts. A custom welding jig ensures pinpoint accuracy for the wick adjuster assembly - solving flame stability while keeping shutdowns quick and controlled.