TOUCHING LIGHT FOREST

When I started working in Dreamdeck as a landscape designer, the conflict between the design department and hardware development has become almost irreconcilable, so I was arranged to work in the factory to see how the touch lamp was developed and came out. However, this version of the touch lamp was using 4 laser ranging sensors to sense hands vertically on 4 laser projection lines, thus making it quite unstable.

Meanwhile, I found that some sort of touch sensor is using wires to sense a hand's closing, and does not need to be physically touched. Based on this effect, I tried dozens of touch sensors and their arrangements, then successfully developed the second version of the touch lamp. It is worth noticing that during the whole process, the development apartment gives no positive support or feedback on it, thus some of the experiments might seem unnecessary.

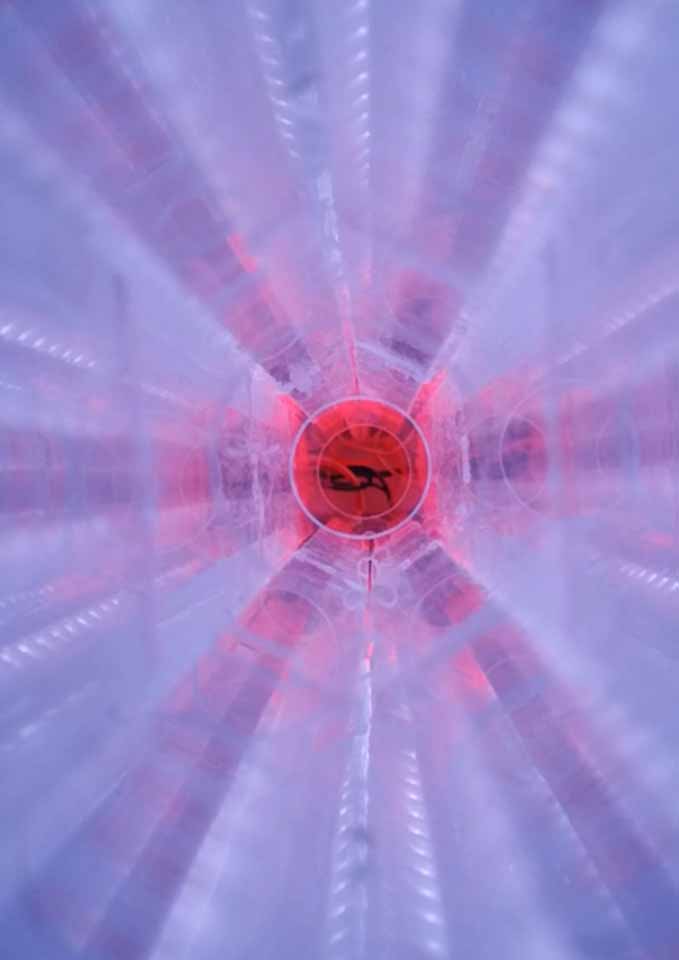

P1 | TOUCH LAMP

- Date: 2019 JUNE-OCT

- Role: Bystander

- HardWare: Laser Ranging Sensor x4; LED strips.

- Description: The first version of touch lamp. By using 4 laser ranging sensors, it can sense tourists' hands vertically on 4 laser projection lines, thus made it quite unstable.

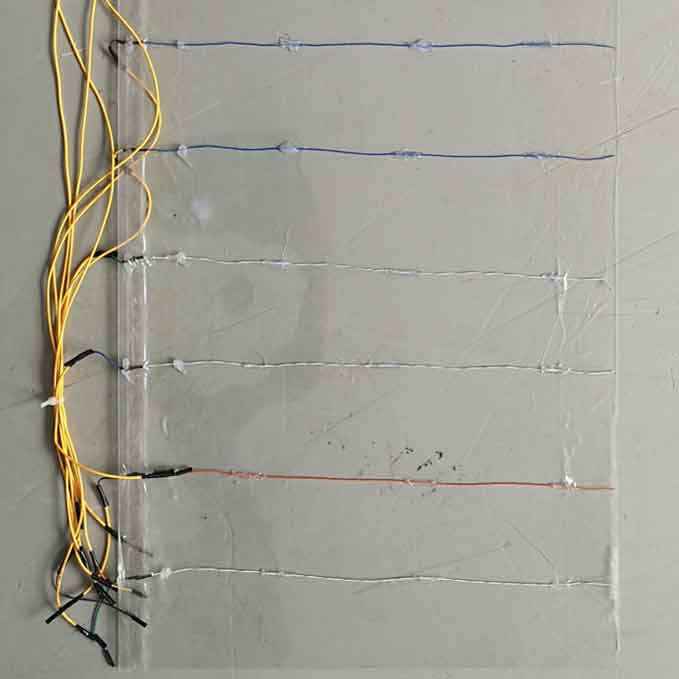

V2 | Touch Sensitive Film

- Date: 2019 OCT-DEC

- Type: Research Project

- Role: Hardware develop

- SoftWare: Arduino IDE; KiCAD for pcb

- HardWare: TTP223, Copper wires, PVC film

- Description: The development of touch-sensitive film. It needs to be placed inside the acrylic tube, and sense the hand's touch on the other side of the tube.

Research

A process of finding the right touch sensor chip, the right capacitance, and the right distance between each sensor chip, through a lot of tests.

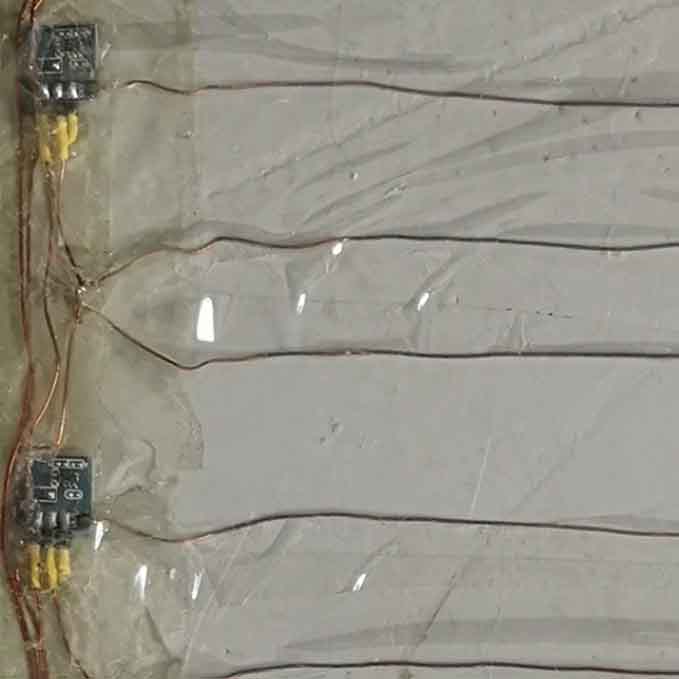

Extended sensing wires: After successfully testing a touch chip and an extension sensing wire, I put the touch chips together and extended the sensing wires in the shape of an 'L'. However, the sensing wires were too close to each other, thus the chips were always on the triggering status.

Array of sensing chips: By putting the chips as a linear array, then extending the sensing wires horizontally, it worked! And seems quite sensitive and stable!

Full-size test: To adapt to a 150mm diameter tube with 10mm thickness, the sensing film should be 1500mm in height and 400mm width. The length of a 6-year-olds toddler's hand is aound 120mm, thus the gap of each sensing chip is set to 60mm. Once again, the first few full-size sensing films shows strong interference between the sensing chips, and always remaining triggered status.

Electric field shielding: After taking lessons about the electric field, I added a zero potential line- line connected to GND-between each sensing line, to reduce the interference between the touch chips. All of these experiments are done in full size.

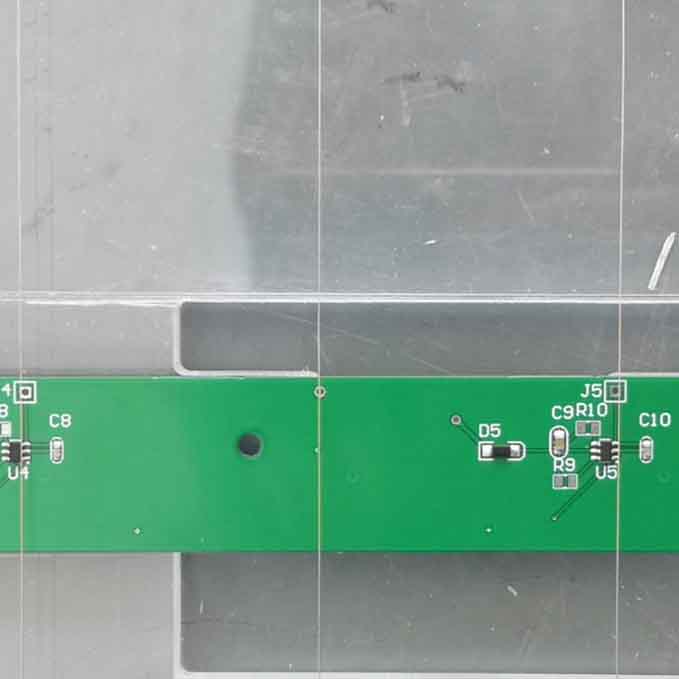

PCB: The final version of the touch film takes 19 TTP223 touching sensor chips arranged on four linear shapes PCBs, and they are glued on 0.5mm thickness PVC film.

Small batch production: To improve the efficiency of assembling the touch films, I made a tooling and went to an assembly foundry to produce them.

PS: The other types of touch sensing chips like TTP226, TTP228, and MPR121 were not tested due to the time limit.

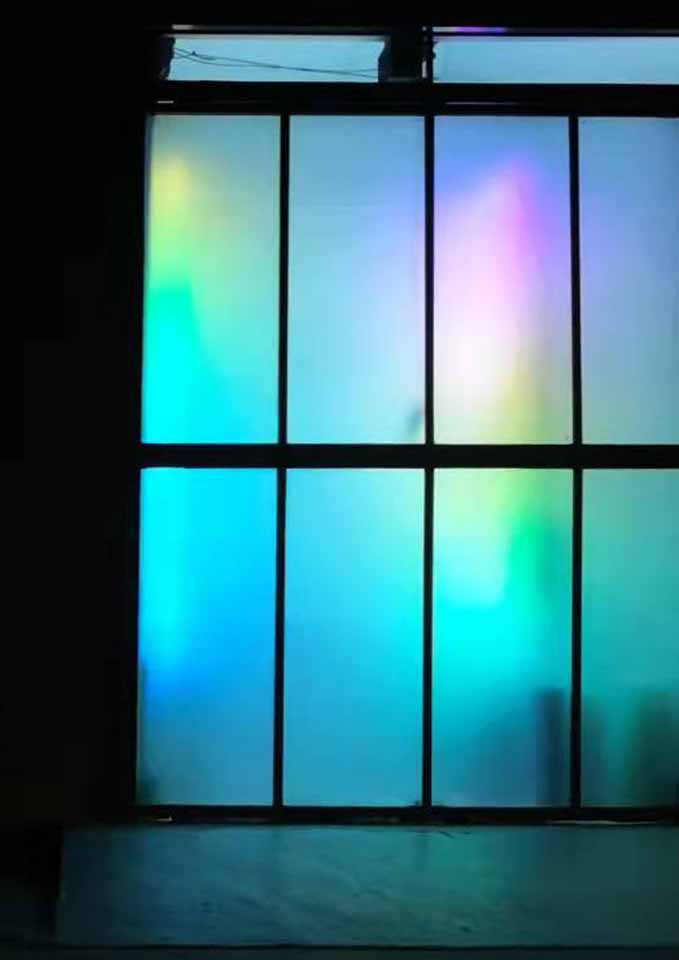

V3 | Structure Design

- Date: 2019 NOV-2021 FEB

- Type: Grounded Project

- Role: Structure Design

- SoftWare: Rhino

- HardWare: PVC tube; PVC board; Steel

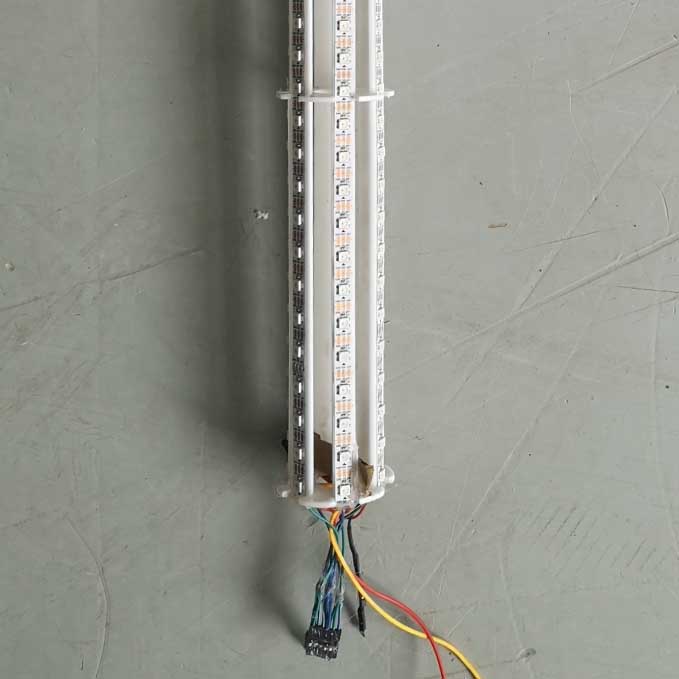

- Description: The light-emitting part should be made of non-metallic material, and can hold 6 light strips; the PCB and the touch film. So I was asked to build a structure prototype at first, then the whole structure design including the sheet metal part.

Research

A process of testing all kinds of laser-cutting PVC, try to find a solution to get the light out evenly.

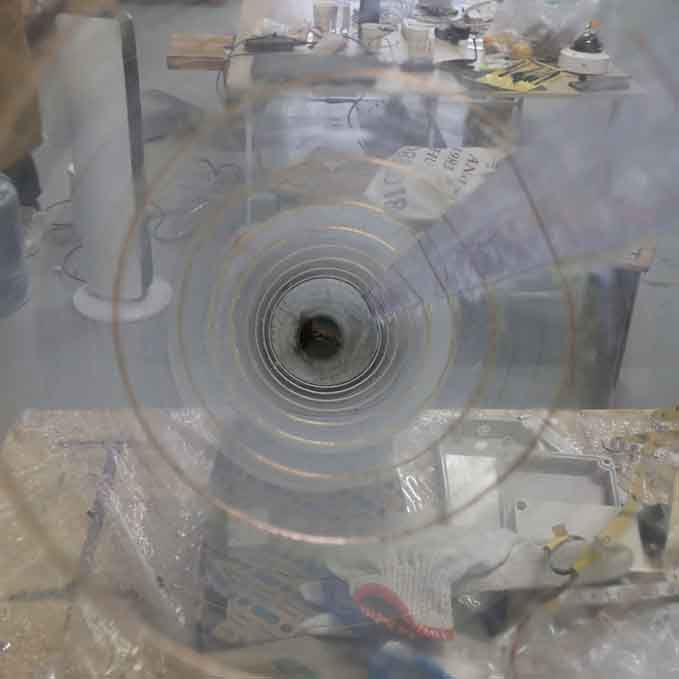

Test sample: A small hexagonal column that fitted into various types of tubes. It was designed to find the best distance from the light strip to the tube's inner wall.

PVC structure: The final structure takes a 10mm, transparent PVC board, as the frame. This makes it beautiful but fragile.

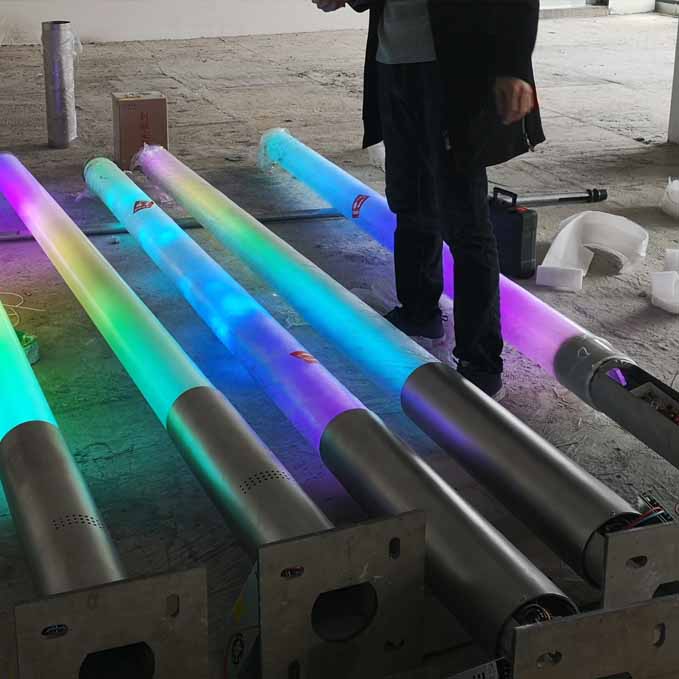

Foundation: The outer metal pipe uses a whole 304 stainless steel pipe, and it can be put down and rotated to lock.

Follow-up

In the process of pushing forward the touch lamp, I had a long-term conflict with the hardware development department, during which I gradually took over the teams of industrial design, structural design, hardware product manager, and factory production. Over the next year, by working closely with the software(UE4) department, we launched over ten products and customized products.

After the touch film was successfully tested, the MCU development of this lamp was assigned to the hardware development department, leading to another long-term conflict. The first batch of touch lamps landed in Zibo, Shandong in April 2020.

The conflicts ended with my team being merged into the hardware development department again, and I went to the project department alone to set up an independent R&D team for customized products and art installations.